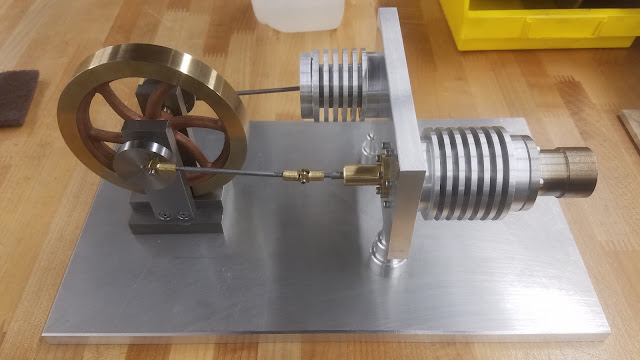

Stirling Engine Manual Lathe/Mill Assembly

To obtain my manual machining certificate I had to machine a Stirling engine assembly from scratch on only manual machines. The Stirling engine can be powered by any heat source, and can run reliably with proper lubrication without producing any waste or pollution, by using heat expansion in a displacer cylinder to push air to the power cylinder. Excluding fasteners (36) the entire assembly consists of 28 pieces. Excluding the cast bronze flywheel and precision ground drill rod, everything was machined from billet material. The material type for the machined pieces include silicone bronze, C36000 brass, 6061 aluminum, graphite, 1018 mild steel, 303 stainless steel, and M1 high speed steel. The tolerances for these pieces vary quite wildly, and can be separated into tight, medium, and loose categories. Starting with loose tolerance components are the base and the bulkhead pillars. The base is a sheet of 1/2" thick aluminum onto which all other components are mount...